Finishing of precision parts

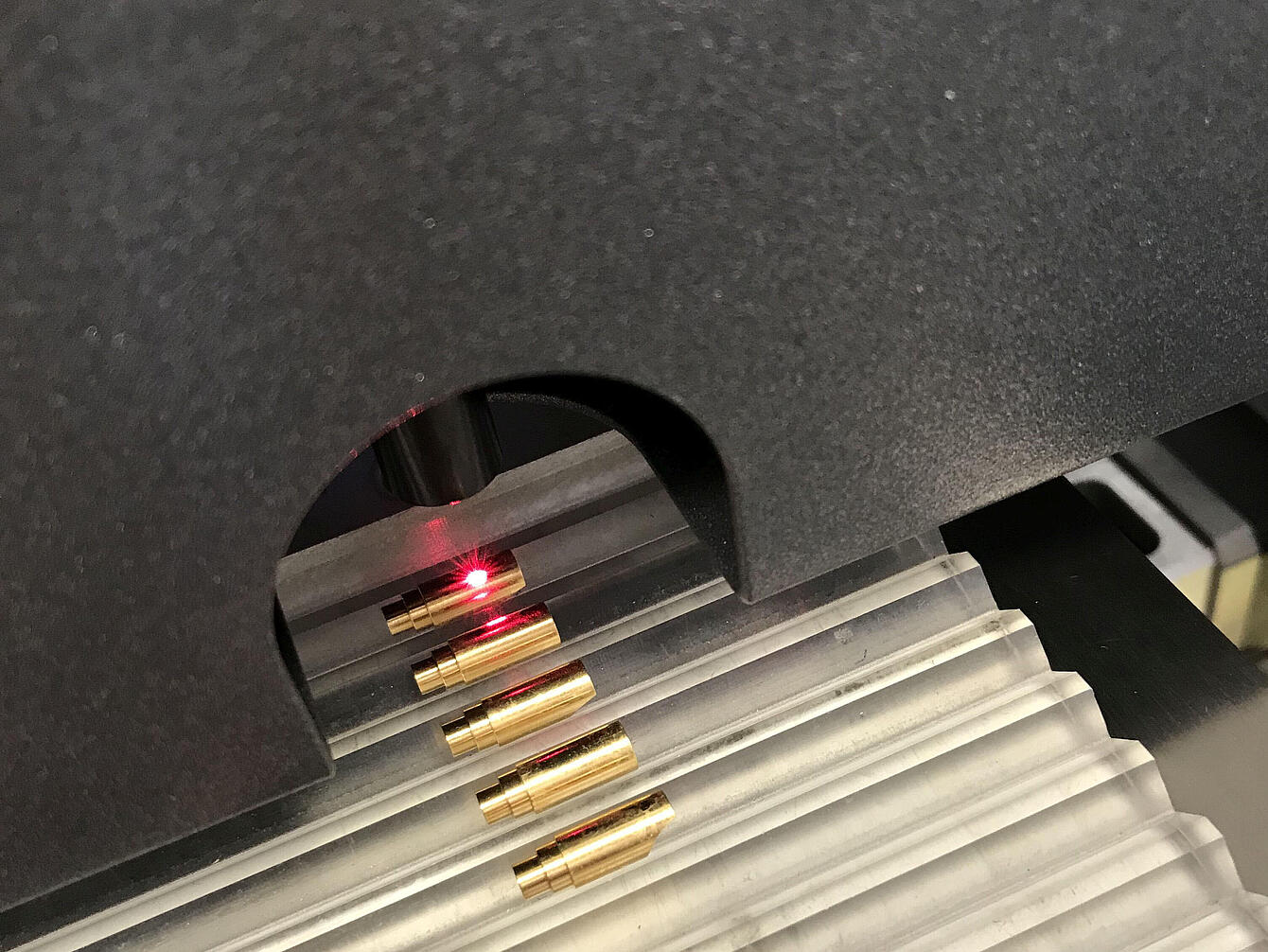

Our main area of expertise is in the finishing of precision parts that need a technical and functional coating. As specialists in commercial electroplating, we coat electrical contacts, contact sockets, contact pins, precision-turned and -punched parts, springs and milled parts, with a special focus on working with gold and silver. Our extensive experience benefits our customers in a wide range of sectors, including electrical connectors and components, electrical engineering, electronics, telecommunications, medical engineering, e-mobility, automotive and aerospace engineering.

The wide variety of bulk-good coating options that we offer and our own in-house developed

selective systems for bulk goods make us a technological leader in gold and silver surface coating.

Quality

binder galvanic surfaces GmbH is ISO 9001:2015- and ISO 14001:2015-certified and guarantees batchprecise traceability with bulk good-processing. So that we can offer our customers the best possible quality, we document intermediate and final tests in a defined test cycle. Our tests always include coating thickness measurements with X-ray fluorescence measurement devices, solderability and adhesion tests in accordance with the applicable standards, and visual checks.

Research and development

The driving force behind our work is our desire to build a partnership with you, starting with your initial idea, through its development and on to final implementation in series production. Our research and development experts ensure that we come up with the most innovative and best possible coating solutions for you.

Flexibility

Our highly motivated employees provide personal support with all electroplating and administrative matters throughout the entire duration of our business partnership. The quantity and variety of resources we have at our disposal mean we can provide you with all the different volumes you need and meet your deadlines. The engineering systems we work with give us a lot of freedom, because we are able to combine manual contract manufacturing with automated system control.

As a medium-sized electroplating company with around 100 employees, we are incredibly flexible.

In-house plant engineering

With our in-house plant engineering and expertise in the areas of electroplating technology, mechanics, sensor technology and automation technology, we are leaders in selective coatings for bulk goods.

Separation and feeding technology in bulk goods and drum technology all play a crucial role for our different electroplating processes.

As we belong to a medium-sized group of companies, we have access to specific expertise ondifferent technologies, particularly in the area of automation.